26 May Taking Your Metal Cutting to the Next Level with Plasmacam Technology

In today’s competitive landscape, businesses and individuals are constantly looking for ways to enhance productivity, streamline operations, and improve overall efficiency. Metal cutting, an essential aspect of industries like manufacturing, automotive, and construction, demands accuracy and finesse. Plasmacam technology offers a groundbreaking solution that takes metal cutting to the next level, providing numerous benefits, and unleashing new possibilities.

What is Plasmacam?

Plasmacam is a cutting-edge technology that employs plasma-cutting techniques to cut metal materials precisely and intricately. It combines computer-controlled systems with high-temperature plasma to achieve clean and precise cuts. Plasmacam technology has gained recognition for its versatility, efficiency, and exceptional results.

Benefits of Plasmacam Technology

Enhanced Precision

Plasmacam technology offers unparalleled precision in metal cutting. With its computer-controlled systems, it can achieve intricate designs and precise cuts, ensuring high-quality end products. The advanced software allows for detailed customization and accurate execution, surpassing traditional cutting methods.

Versatility

One of the standout features of Plasmacam technology is its versatility. It can effectively cut a wide range of metals, including steel, aluminum, brass, and copper. Whether you require straight cuts, beveled edges, or complex shapes, Plasmacam technology delivers outstanding results across various materials, expanding the possibilities for creative designs and applications.

Time and Cost Savings

Traditional metal cutting methods often involve labor-intensive processes and extensive setup times. Plasmacam technology significantly reduces both time and cost by automating the cutting process. With computer-aided design (CAD) software and CNC control, Plasmacam ensures efficient operations, minimizing material waste and optimizing productivity.

Customization

Plasmacam technology empowers users to bring their creative visions to life. The advanced CAD software enables intricate design modifications, allowing for personalized and customized metal cuts. From industrial applications to artistic endeavours, Plasmacam technology enables unmatched customization options.

How Does Plasmacam Work?

To fully grasp the capabilities of Plasmacam technology, it is essential to understand its underlying processes and components.

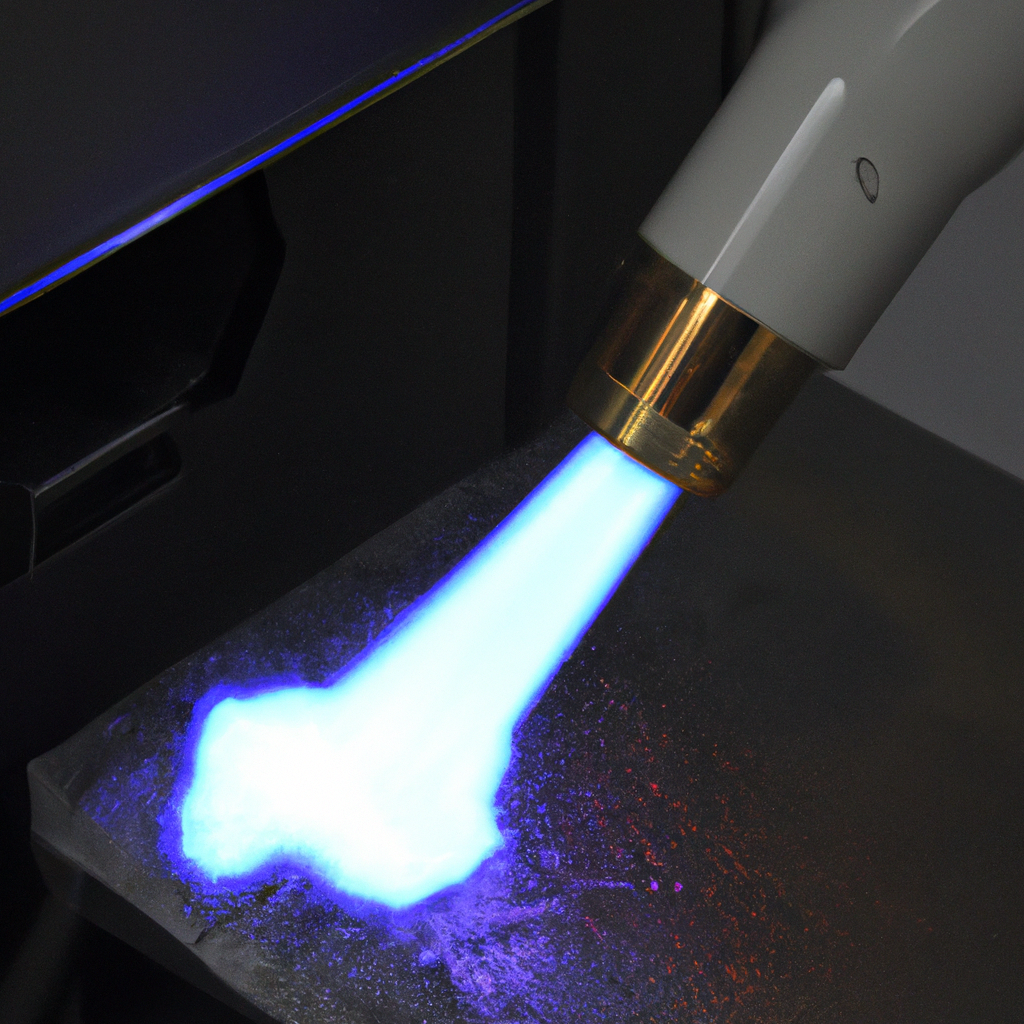

Plasma Cutting Process

Plasma cutting is a thermal cutting method that utilizes a high-velocity jet of ionized gas, known as plasma, to melt and remove material. Plasmacam technology harnesses this process to achieve precise cuts on various metals. The plasma cutter emits a focused stream of plasma, which rapidly heats and melts the metal, while a high-pressure gas removes the molten material, resulting in clean and accurate cuts.

Computer-Aided Design (CAD) Software

Plasmacam technology integrates computer-aided design (CAD) software, enabling users to create intricate designs and patterns. The software provides a user-friendly interface where designs can be drawn, modified, and customized. With a vast library of tools and features, the CAD software ensures precise execution and maximizes creative possibilities.

CNC Control

The computer numerical control (CNC) system is at the core of Plasmacam technology. It interprets the designs created in the CAD software and translates them into precise cutting instructions for the plasma cutter. The CNC control ensures the accuracy, speed, and repeatability of the cutting process, allowing for consistent and high-quality results.

Applications of Plasmacam

Plasmacam technology finds applications across various industries, offering immense value and versatility.

Metal Fabrication

In the field of metal fabrication, Plasmacam technology is a game-changer. It enables the creation of intricate and complex metal components with unmatched precision. From structural elements to decorative designs, Plasmacam technology empowers fabricators to elevate their craftsmanship and deliver exceptional results.

Automotive Industry

The automotive industry relies on Plasmacam technology for a range of applications. From cutting metal parts and panels to creating custom exhaust systems, Plasmacam technology streamlines the manufacturing process and enhances efficiency. Its ability to work with different metal types and execute intricate designs makes it an indispensable tool in the automotive sector.

Sign Making

Sign making is another area where Plasmacam technology excels. It enables the production of eye-catching and intricately designed signs with precise cuts. Whether it’s large outdoor signs or intricate indoor displays, Plasmacam technology offers sign makers the freedom to bring their creative ideas to life.

Art and Sculpture

Plasmacam technology has also made its mark in the world of art and sculpture. Artists and sculptors can utilize the technology to transform their visions into reality. From metal sculptures to intricate art pieces, Plasmacam technology unlocks new creative possibilities and allows artists to push boundaries.

Advancements in Plasmacam Technology

Plasmacam technology continues to evolve, incorporating advancements that further enhance its capabilities and broaden its applications.

High-Definition Plasma Cutting

The introduction of high-definition plasma cutting has elevated the precision and quality of cuts achieved with Plasmacam technology. This advancement enables even finer cuts, sharper edges, and smoother finishes, pushing the boundaries of what can be achieved with metal cutting.

Multi-Axis Cutting

Plasmacam technology has also embraced multi-axis cutting, enabling the creation of complex three-dimensional shapes. By controlling the movement of the cutting head along multiple axes, Plasmacam technology opens new possibilities for intricate designs and precise cuts on curved surfaces.

Integrated Nesting Software

To optimize material usage and reduce waste, Plasmacam technology now integrates nesting software. This software efficiently arranges the metal components to be cut on a sheet, minimizing scrap material, and maximizing material utilization. Integrated nesting software ensures cost savings and environmentally friendly practices.

Case Studies: Success Stories

Numerous businesses and individuals have experienced remarkable results by incorporating Plasmacam technology into their metal-cutting processes. From custom metal fabricators to automotive manufacturers, success stories highlight the transformative impact of Plasmacam technology on their operations, efficiency, and overall quality.

Conclusion

Plasmacam technology offers a revolutionary solution for taking metal cutting to the next level. Its precision, versatility, and advanced features make it an indispensable tool in various industries, including metal fabrication, automotive, sign-making, and art. With continuous advancements and success stories showcasing its capabilities, Plasmacam technology empowers professionals to achieve exceptional results, enhance productivity, and

Sorry, the comment form is closed at this time.